10 EASY TIPS TO IMPROVE YOUR TUBELESS TIRE EXPERIENCE

What you need to know to be fast—and safe

By Troy Templin

Here’s a funny thing about the tubeless revolution currently afoot in the bike industry—it’s really nothing new. Currently, while there’s a big debate about the efficacy of hooked-versus-hookless rims with tubeless tires, you’ve been rolling on hookless rims on your car or your motorcycle since time immemorial. In fact, bicycle wheels, too, have been hookless, then called straight-sided for decades until the bike industry moved to hooked rims (Crotched) as a means of countering diminishing production standards and higher pressures.

Road tubeless isn’t new, but the amount of suitable products to the category has exploded in the last two years. Much of this is due to the gravel category that has redefined the drop-bar category. Gravel has exposed the road category to tire sizes beyond 23mm while redefining the boundaries set on road bikes generations ago. Tubeless for bicycles was started by Mavic way back in 1999 with their UST system, but it wasn’t until 2001 when Stan’s NoTubes really changed the tubeless market. While UST never really took off, it did help set the foundation for where we are today.

The problem today is that despite over 20 years of R&D, much of the information pertaining to tubeless use is outdated and, even worse, it doesn’t apply to current road offerings at all.

WHAT HAVE WE LEARNED?

Any tire’s air volume is far more influential to tire pressure than rider weight. Mountain bike riders have known this for years, but until a few years ago there wasn’t much documented information for tires of all sizes. As gravel and all-road riding have gained popularity, more brands have begun to adopt frame clearance for larger tires, leading to an industry-wide acceptance, but more important is an understanding of what benefits lower air pressures and higher volume can offer a rider.

As a quick example: if a 180-pound rider is on a 23mm tire, the recommended pressure is around 82–86 psi, but for years we were told it needed to be 90 psi or higher; why? Because on a 21mm or even 18mm tire that is true. For years 18–21mm were the standard, and at 180 pounds, a rider would need over 100 psi because the air volume is so low. As the industry moved to 23mm and 25mm, an abundance of lab and aero data showed that in perfect conditions an unweighted tire at higher pressure offers a lower rolling resistance. But, in reality, we don’t ride in perfect laboratory settings, and in the real world even the smooth, perfect roads are more than twice as rough as a lab setting.

So, that same 180-pound rider on a 28mm tire should opt for a pressure of 62–65 psi as a starting point, and this is with or without a tube. Sure, tire construction and riding position will alter these, but only by around 1–2 psi. As volume is added, the pressure starts to lower, and this is how we have arrived at the point where road bikes can run hookless beads (but more on that later).

Most modern road bikes now come stock with 25–28mm tires but with room for 30–32mm. All-road/endurance bikes come with 30–32mm tires and room for 38mm, while gravel bikes come with 700x40mm or 650x47mm with room for even larger tires. As a rule of thumb, I suggest a rider choose a tire size that allows them to run 65 psi or lower when riding road tubeless.

SO MANY VARIATIONS

Now that previously recommended (aka “old school”) pressure numbers have been debunked, we can move to all the options that surround tubeless.

Tubeless is essentially a system of parts that, as the name implies, eliminates the need for a tube. This doesn’t mean you can’t use a tube, but, more important, for the system to work all the components have to work in conjunction with each other. This was what made Mavic’s original system so dependable—it was designed to work as a system. There is the rim, tire, valve, sealant and, in most cases, some sort of internal spoke-hole sealer (normally a form of impermeable tape).

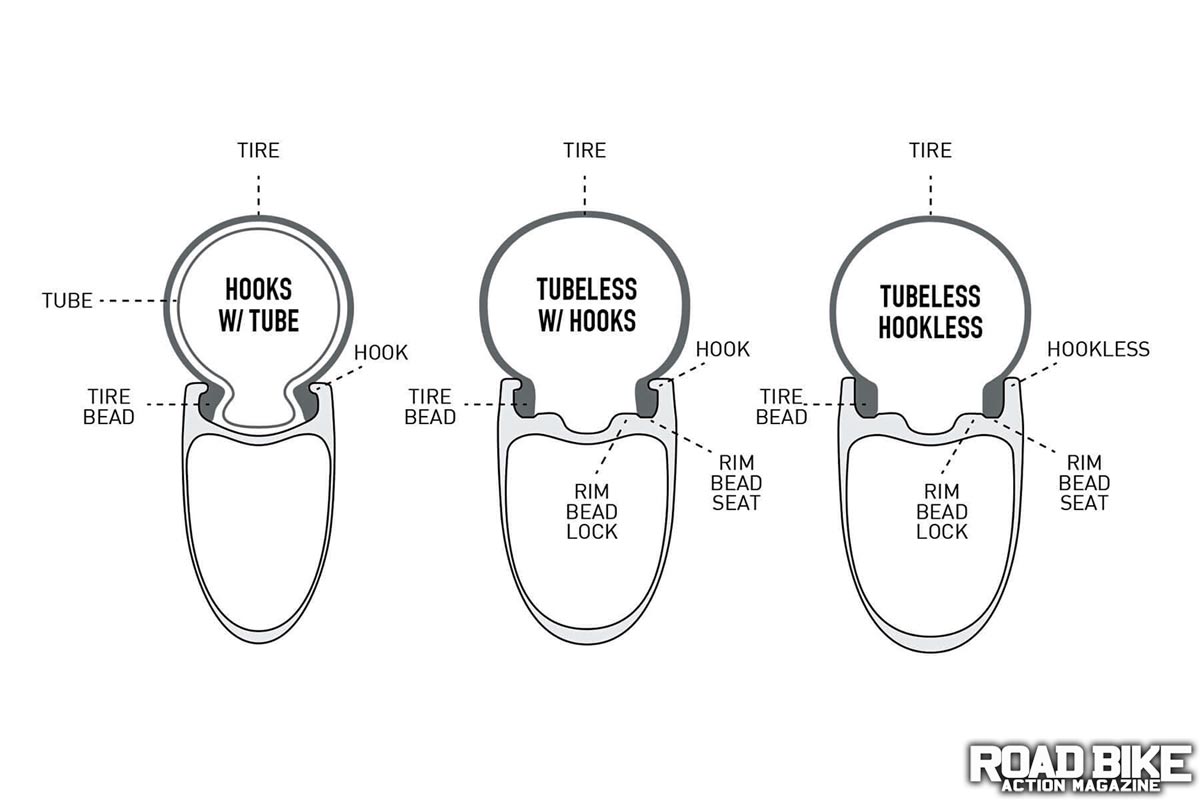

Rims now come in two tubeless variations—hooked bead wall and a hookless bead wall. A hooked bead wall is the design we have been using with tubes, with the wall of the rim that holds the tire in place and has a hook but with a modified rim bed to make them tubeless-compatible. As the name implies, a hookless bead wall has no hook and so relies on the tire-bead construction to stay on the rim. The hookless rim design also allows the rim material to be thicker and more robust.

Since tubeless relies on much more refined and exact dimensions from both the tire and rim, the hook of a rim is only needed when using a non-tubeless tire. This is because the acceptable variance in tire and rim design for tube-type products is so vast that the hook offers a physical stop and point of added friction when paired with a tube.

Key to remember, a hookless rim always needs to be paired with a tubeless (or tubeless-ready) tire. A tube can still be used, but the tire must meet the tubeless requirements. Additionally, most hookless rims use a maximum tire-pressure rating as a safeguard because there is no physical hook to stop an over-inflated tire bead from exceeding the rim lip. In many cases, this pressure exceeds the max pressure that even the heaviest of riders would need for the tire size the wheel is designed for.

Many hooked bead-wall tubeless rims will also have a max pressure as well. This would apply to tubeless for sure, and in many cases tube-type tires, too. This is because as we transition away from rim brakes to discs, we no longer need the overbuilt brake track that rim brakes required. This means designs and materials that are optimized for weight and impact rather than heat and wear.

WHAT’S MOST VERSATILE?

In general terms, a hooked bead-wall rim will be more versatile for a rider that doesn’t always want to use a tubeless tire. This comes at the cost of impact durability, because to create the hook or lip of the wall, the rim-wall material is normally reduced. Since a hookless bead wall is not machined out, it provides more structure and, in turn, more durability, which helps in low-pressure situations.

A properly designed tubeless rim, hooked or hookless, will have bead-shelf ridges or bead-retention ridges (same thing). These ridges sit between the bead shelf and bed of the rim. They help hold and maintain the tire bead on the rim’s bead shelf and against the rim’s bead wall. Most will be between 0.3–0.5mm tall and very important for a hassle-free tubeless experience. If these ridges are absent, then at low pressure (under 20 psi) a tire bead will slide into the rim bed and lose its seal. This is important when adding/refreshing sealant or in the case of a puncture. It is also worth nothing that these ridges are not necessary to meet tubeless standards, but we recommend picking a rim that has them.

A common question that we get is, can I convert my rims to tubeless? This was popular on mountain bikes in the early 2000s, and because of the low pressures used, it was possible. For road and gravel riding, you should

never attempt to make a non-tubeless rim tubeless.

SEALING A RIM

The importance of properly sealing a rim for tubeless might be the most overlooked aspects of a tubeless setup. The rim bed is where most wheels will have spoke holes. This means they need a tape or rim strip that can seal those holes to prevent air and sealant leaking. In our experience, 90 percent of tubeless complications come from poorly sealed rim beds. This is extra important for two reasons: 1. Because the rim profile on most carbon rims is not designed to withstand internal pressure, any rush of air entering the rim cavity can cause a catastrophic failure as a rim’s profile sidewall on a carbon rim cracks from the pressure. And 2. Because some sealants contain ammonia and are corrosive, a leak could lead to nipple/rim corrosion and failure.

Although the jury is still out on whether you want a wall-to-wall rim tape or just enough to seal the spoke holes, we always opt for wall-to-wall. This is because the bead of the tire will help hold the tape in position. We also recommend wrapping the rim twice around to ensure there is substantial coverage.

If you have a tubeless rim that seems to be losing air but there is no sign of sealant leaking from the tire or bead, then most likely it is leaking through the rim cavity. This should be resolved immediately because, as noted above, any large impact could transfer enough pressure into the rim cavity, causing likely damage.

The tubeless valve can also be an area of misconception when it comes to tubeless. Our rule of thumb is the hole in the rim tape needs to be minimal and let the installation of the valve enlarge it. Most valves will have a rubber grommet that helps seal around the hole and valve using a threaded nut that is on the exterior of the rim. This nut should be tight, but be careful because over-tightening it can cause failure of the rubber grommet. Also, note that some valves come with different-shaped grommets for different rim bed shapes, so if you’re having trouble sealing a valve, try a different grommet or valve design. In many cases, even the ones supplied with the rims are not ideal.

THE TIRE EVOLUTION

Tubeless tires have come a long way since they went mainstream nearly 20 years ago and most of the road performance gains have been in the last two to three years, with 2020 bringing the most improvements for 25–32mm tires. The most important changes have been to the construction of tires with more defined standards for rim and tire interfaces. Not all brands have met these new standards, so look closely if your preferred rim or tire brand has a compatibility chart or list.

“The problem today is that despite over 20 years of R&D, much of the information pertaining to tubeless use is outdated and, even worse, it doesn’t apply to current road offerings at all.”

Just as it’s true with tube-type tires, the lighter the tire, the less durability. Tubeless tires do weigh more than their tube-type counterparts due to the added bead reinforcement needed to maintain size standards, as well as the rubber needed to seal them so that they are air-impermeable. For this reason alone, expect most 28mm performance tires to be around 280–300 grams each, and gravel tires in size 40mm to be in the 450–500-gram weight or more depending on the level of built-in protection.

THE MAGIC OF SEALANT

What really sets a tubeless system apart from a tube is the sealant. This is because if the tire gets a small puncture, the liquid sealant in the tire will seal the hole within seconds. In many cases, the rider will not even realize they have had a puncture. This is where some of the misconceptions come from, because this can happen so often without realization that a tubeless user might not realize how many flats they have deterred.

Things to consider when choosing tubeless sealant are your riding conditions and environment. Tubeless sealant will dry up and on average last four to six months. Heat is a big factor, and the hotter the temperatures, the faster sealant seems to dry out. Some sealants don’t work properly in colder temperatures, either, so check the manufacturer’s ideal conditions. We’ve also found that tubeless systems will lose pressure when left sitting for a long period of time and last longer on bikes that get a lot of use.

“If you have a tubeless rim that seems to be losing air but there is no sign of air leaking from the tire or bead, then most likely it is leaking through the rim cavity.”

As mentioned above, some sealants contain a small percentage of ammonia to stabilize the liquid. This can be catastrophic to brass or bare alloy, so you don’t want it in your rim cavity where the spoke nipples are. Most carbon rims also have pressure-relief holes on the side of the rim to let slow-leaking air escape in case of a defective or leaking tubeless system. If those small holes are sealed by internal leaking sealant, then it could cause an entire rim to explode as a rush of air enters the rim cavity.

At the end of the day, whether you choose a tubeless system or not, we have come a long way in tire technology and real-world results. Gone are the days of 90-plus pressures in replacement for the benefits of compliance and traction with lower rolling resistance. With the added knowledge of pressure versus weight, all tire types of tube and tubeless gain the benefits.

WHEN TUBELESS GOES WRONG

Why would Specialized backtrack? Blame the pros…

How does a company like Specialized launch a new line of wheels that are designed with tubeless-specific shapes look like they have the appropriate specifications, and even come with tubeless accessories but then claim they are not tubeless in 2020?

Let’s step back a few months when Specialized dropped off the new Tarmac SL7 to the palatial, well-lit RBA office. This was back in June, about a month or two before the official launch, and they were, as usual, telling us how great the SL7 was. Much of the focus was around the pinnacle S-Works models. We clearly remember noticing the different front-to-back profiles on the Roval wheels and asking what the deal was. The Specialized reps told us that they would connect us with the Roval team, as they were still working on the final launch details.

We were left with the SL7 Pro model (RBA, October ’20), which would be delivered to dealers with a new set of Roval Rapide CL wheels. These wheels don’t seem to be available for aftermarket and were not in our Roval launch material. Since our test bike was built and ready to ride, there was no small parts box or materials included.

Following the web post of our first-ride review, quite a few people inquired about the wheels and whether they were tubeless. Then the team at Roval and Specialized reached out to see if I would update my review, saying they were not intended for tubeless use. This came as a surprise, because while I rarely read the press kits telling you all the “great things” about a bike, I was sure I had deliberately removed the tires from both wheels to check internal construction, as well as to take my own measurements.

JUST ASK THE SMART GUY

As it happens, one of our local test riders is also a NASA rocket scientist (as in, he’s smarter than us), and I asked him to bring the bike back so we could check the wheels and get his feedback. He is not an official expert in bike wheels, but he has raced for a world champion jersey on the track (leaving with a respectable bronze) and is a passionate cyclist. Upon yet another inspection of the rims, our assumptions were correct.

“As the project evolved and they got further into the development to be tubeless, they realized they would have to make compromises to the total system weight, as their pro teams prioritized weight savings over tubeless capability.”

The Roval wheels have all the telltale signs of a tubeless design. They are internally wide at 21mm, they have a large bead shelf for the normally more robust tubeless beads, and there is a distinct 0.4mm (ETRTO max) rim bead ridge/lock (not required for tubeless but never on a non-tubeless rim). The bed of the rim is fairly shallow for easier tubeless setup, too. Last is the use of Roval tubeless-ready rim tape to put a little icing on the cake.

Our local smart guy commented that in his opinion they were designed to be tubeless and, in fact, a better design than many others we have tested. His comment was that if Roval was claiming they were not tubeless, that likely meant that something didn’t pass inspection at the last minute and they were too invested to change it. Funny, but that was just what we were thinking!

CONTENTION AND SUPPOSITION

Maybe the bead shelf wasn’t the correct diameter (we don’t think this is the case) or testing showed the bead wall could fail when running overinflated pressure (we doubt that, because it would affect a tube setup, too). Our guess was it was more likely that the full line of Specialized tires was not compatible. For us, all the (different brand) tubeless tires we tried with the wheels had worked just fine. We have not done any long-term tests, but the setup of the bead retention while deflated and performance on a handful of rides was flawless.

Initially, neither Roval or Specialized responded to our request for more info, but instead just asked that we not promote the wheels as being tubeless-friendly. We reached out to a few of our local shops and have gotten mixed feedback. Some have said that the first few complete bikes with the new wheels came with tubeless valves in the small parts box, but since then they have not been included.

WHAT WE RECOMMEND

We would always encourage people to read all the new bike/accessory instructions and follow the manufacturer’s specifications. We’re happy to see how road tubeless has evolved quickly in the last two years with much better performance, reliability and compatibility, but as you can see, mistakes still happen at the highest levels.

Enve has a tire-compatibility list for their different wheel lines. Most of the incompatibility comes from tires not meeting the hookless requirements that some of their wheels have. We personally had no issues with our tubeless attempts on our Rapide CL wheels. The addition of the beadlock (previous Roval road tubeless rims didn’t have this) makes it much easier to maintain a tubeless system and the reason we believe there is more to the story than Specialized will tell. Without any initial response from Roval and Specialized, we couldn’t properly determine the true risk of utilizing a tubeless setup on their new Rapide and Alpinist wheels, and for that, we would steer clear until there is more information available.

FINALLY, A RESPONSE

After running this story on our website, Roval reached out to try to further clarify the situation. They told us that they had a lot of goals going into the wheel project and tubeless was a top priority. As the project evolved and they got further into the development to be tubeless, they realized they would have to make compromises to the

total system weight, as their pro teams prioritized weight savings over tubeless capability.

This is why they say the internal design resembles a tubeless rim, because in reality, it was a carryover from their knowledge gained in designing the tubeless Terra gravel wheels. In their testing, they also found that the bead ridges/lock holds tube and tubeless tires on the rim tight even when flat, making them safer in real-world conditions.

Having tires roll off rims is a huge worry for pro teams and one of the main reasons WorldTour pros remain on tubulars. Even after Specialized’s own testing showed that tubulars are less aerodynamic, have higher rolling resistance than tube-type tires and, to be honest, a pain to maintain, tubulars are the go-to choice for racers.

THOSE PESKY PRO RIDERS

So, what is the problem? Roval says the need to save weight was the final nail in the coffin for tubeless. But, the internal rim seems to meet all the standards, so where is the weight? We can only assume that the real problem lies in the profile of the rim. The profile of the rim was never made to withstand pressure, but as we have experienced while testing, if the rim is not sealed correctly, there is a chance that the pressure in the tire can be transferred to the rim’s profile cavity and cause catastrophic failure.

We have had prototype wheels from other brands that experienced this type of failure. From our experience, this only happens if there is a failure in the rim tape or it is not installed properly. Specialized is a large company, and they most likely didn’t want to take that risk and knew that the profile would need to be reinforced to prevent this rare failure.

This is, of course, speculation on our part, but it’s the only thing that we can assume with the facts and knowledge we have. When we look back on the other wheels that failed from this rare situation, those brands added additional carbon reinforcement to the rim wall for their production versions, because they knew the end user now understands (and accepts) that the performance gains of tubeless are more beneficial than saving less than 100 grams.

As a side note, the new Rapide wheels are deeper, wider, have more robust bead material (in the front) and are lighter than the previous CLX 50 Roval wheels. As the brand most likely tries to move their pro teams off of tubulars and to faster and more efficient tubeless systems, they knew that less wheel weight would be easier to sell them on than tubeless. Of course, with the predictable result being Specialized touting Julian Alaphilippe’s Tour de France stage win using clinchers.

While baby steps have to be taken with the pro peloton, the result is that the paying customers have to wait to get their money’s worth. The alternative is to just look at other brands or, like us, take the risk and just make sure

your rim tape is perfect. And like our tubeless breakdown explains, you should stay under 65 psi, because

Roval won’t warranty a tubeless-caused failure.

![]() THE MODERN WORLD OF ROAD TUBELESS TIRES

THE MODERN WORLD OF ROAD TUBELESS TIRES

Plenty of options, but taken with a dose of caution

For many years there have been two options for road tires—tubular and tube type. Within each are many options, but most tubulars were designated for more race-specific applications, while the vast majority of recreational riders would prefer to run with the tried-and-true inner tubes.

Although tubeless is the new name in the tire game for road riding, the technology has been around for over 20 years, but the majority of its popularity was in the higher-volume, lower-pressure realm of mountain bikes and, more recently, gravel.

Now that the old-school notion that max air pressure equals max speed has been debunked, road riders are free to think about what tires to use in a new light. In place of the old way is a new concept that smooth equals fast and more traction doesn’t lead to higher rolling resistance.

With our gained knowledge and understanding of real-world-versus-laboratory performance, the industry has made huge strides in road tubeless. Still, there is a definite need for thoughtful consideration when mixing and matching different rim and tire combinations. Collected here are only a few of the quickly evolving and wide range of tire options.

A few things to remember, just as has been common with tube-type tires of the past, tire manufacturers have suggested pressures printed on the sidewall of the tire. In our opinion, these pressures are worth some second-guessing and, for safety reasons, not the best source to determine real-world pressures. We recommend finding a reliable source or chart to determine tire pressure after you have taken into consideration rider weight, type of riding planned and the physical size (versus the labeled size) of the tire.

Remember, too, that the same tire on two different rim profiles can measure differently, and thus in need of slightly different pressures. When determining the adequate tire pressure, also take into account atmospheric temperature changes and how they will affect pressure throughout your ride. As the heat rises, so does your tire pressure, so you might need to start lower if you roll out just before the heat kicks in.

THE BAKER’S DOZEN

KENDA VALKYRIE TLR PRO

Kenda’s newest addition seems to hit all the marks for a performance road tubeless tire. The 28mm tire hit the scales at 288 grams with a solid bead and easy installation. The tire feels supple with great wet and dry traction. There is a tread-wide-only protection layer to minimize rolling resistance while maximizing weight and protection. The TLR is available in sizes 23–30mm.

Weight: 288 grams (28mm)

Price: $85

GOODYEAR EAGLE F1 SUPER SPORT

A few years ago Goodyear launched a line of cycling tires that performed well but targeted a wide range of riders. Now, they have released a few options for the more performance-oriented rider. Their Eagle F1 Super Sport is offered in 25 and 28mm with no protection, while the Eagle F1 is available in 25-32mm and has a single tread-width protection layer. These tires are easy to mount and have great air retention from our testing.

Weight: 283 grams 28mm

Price: $65

ENVE SES ROAD 29

Utah-based Enve Composites has been at the forefront of road tubeless on the rim side of things and now completes the system with their own tires. Enve is offering 25, 27, 29 and 31mm tires, and with their extensive testing have a well-documented fitment chart when matched to their wheels. They are hookless and hook-bead ready, and they claim the bead will not stretch over time. The shape and performance are best paired with Enve wheels but are compatible with other brands.

Weight: 272 grams 29mm

Price: $75

MAXXIS HIGH ROAD

While the majority of the Maxxis catalog is consumed by dirt-oriented tires, they have a few options for pavement, too. The High Road comes in sizes 25mm and 28mm, and is a durable tire for training and performance. The tire has a 170-tpi construction with a tread-wide puncture layer for added durability without reducing performance.

Weight: 324 grams 28mm

Price: $65

SPECIALIZED S-WORKS TURBO RAPIDAIR 2BLISS READY

Specialized has been one of the leaders in tubeless road tech—that is until lately —and the S-Works Turbo line of tires is their premium offering. The tire is offered in sizes 26, 28 and 30mm and is performance-oriented. It is designed to offer the ride quality of tubulars with the versatility of a hook-type tire with 120 tpi. The S-Works Turbo Rapidair 2Bliss Ready also has a single layer of protection along the tread for even better durability.

Weight: 306 grams 28mm

Price: $80

ZIPP TANGENTE SPEED RT28

Zipp is all about max speed and performance, and their race-specific Tangente Speed tires come is sizes 25 and 28mm. The tire has a single layer of protection for durability. The tire has 127 tpi keeping it supple. Zipp says they are hook- or hookless-compatible, and in our testing, these are some of the most durable road tubeless tires we have used.

Weight: 340 grams 28mm

Price: $80

BONTRAGER R3 TLR

Trek’s Bontrager brand has a full line of tubeless wheels, and the R3 is their go-to road tubeless offering. The R3 comes in sizes 25, 28 and 32mm, and is a balance of performance and durability. There is a protective layer in the 170-tpi construction, and they claim it is best paired with their system of wheels. In our testing we have had mixed reviews, but the price makes them an option to consider.

Weight: 294 grams 28mm

Price: $55

PIRELLI P ZERO RACE TLR

While the name has “Race” in it, this tire is equally qualified to be a performance training tire. There is a tread-wide puncture layer built into the 120-tpi casing for added durability. The tire is offered in 24, 26, 28 and 30mm. Pirelli does note that the 24 and 26mm options are not compatible with hookless rims per the ETRTO standards, but the 28 and 30mm versions are.

Weight: 298 grams 28mm

Price: $80

SCHWALBE PRO ONE

Schwalbe has been one of the leaders in road tubeless options, and their new Pro One delivers a lightweight option that still has a protection layer. The tire is offered in sizes 25, 28, 30 and 32mm with two different constructions available. They also offer a slightly heavier option that is also a bit more durable in the One series, and it is slightly less expensive at $62. Both Schwalbe Pro Ones offer very easy mounting and supple road feel.

Weight: 270 grams 28mm

Price: $81

CADEX RACE

Cadex is Giant’s in-house tire brand, and they are designed to pair with their premium race-oriented wheels that feature a hookless bead. As a result, the bead of the tire is very robust, but the casing is very supple and is said to have built-in protection that is weaved in rather than layered on. The tire is not the lightest, but mounting has been one of the easiest, and the feel is comparable to tires of lesser construction.

Weight: 335 grams 28mm

Price: $100

VITTORIA CORSA SPEED GRAPHENE 2.0

Vittoria has a full line of tubeless options, and the Corsa Speed is the pinnacle but only offered in 23 and 25mm. The 320-tpi construction of the tire is very minimal, and we have had mixed experiences mounting them. With that said, once setup, they offer a tubeless feel that is unmatched. Durability is not their forte, but this would be a top pick to minimize rolling resistance. For a wider range of sizes, durability and training, look towards the Control or Rubino version. The Corsa Control in 30mm weighs in at 318 grams.

Weight: 229 grams 25mm

Price: $84

MICHELIN POWER ROAD TLR

Michelin is now offering a performance-oriented road tubeless tire. It is offered in sizes 25, 28 and 32 with a 120-tpi construction. With minimal layers, it has low-rolling resistance while running

lower pressures.

Weight: 255 grams 28mm

Price: $80

www.motorcycle.michelinman.com

CONTINENTAL GRAND PRIX 5000 TL

Continental has jumped into road tubeless segment with their new 5000 TL. The tire offers the same aspects as the non-tubeless, like their BlackChili compound that prioritizes speed and grip over wear. They offer 25, 28 and 32mm with a tread-wide protection layer for added durability. In our testing we have had very mixed reviews from mounting to bead durability. We would be hesitant to recommend this tire with the number of problems we’ve had, and it might have missed the mark for tubeless on the first go.

Weight: 321 grams 28mm

Price: $95

Comments are closed.